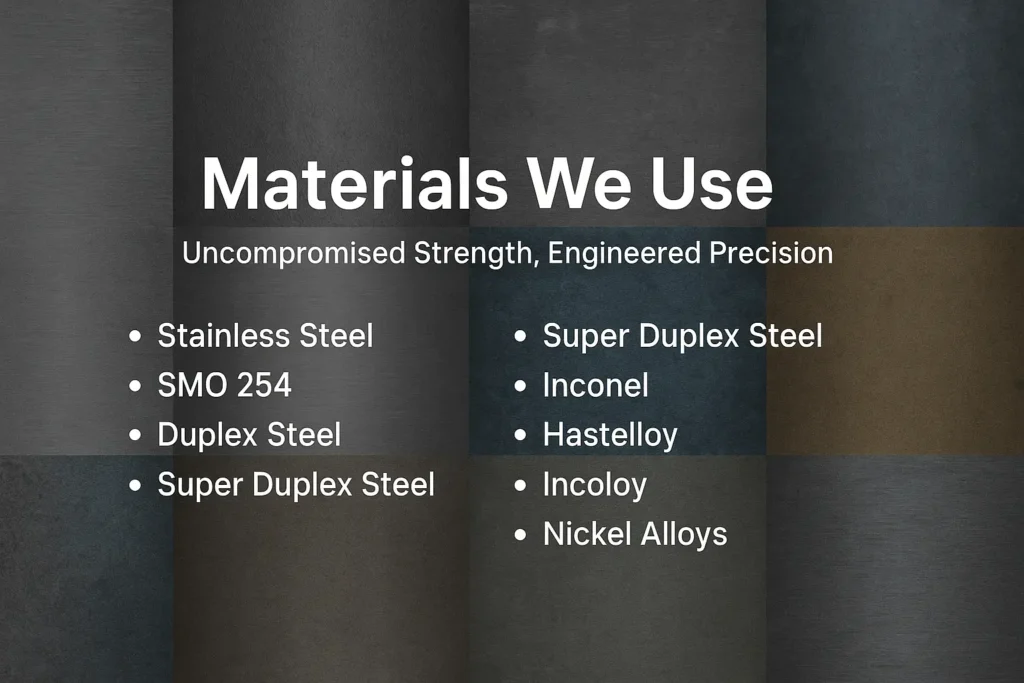

Materials We Use – Uncompromised Strength, Engineered Precision

At SM Fasteners, quality begins at the core — the material. Every bolt, nut, and stud we manufacture is a product of tested metallurgy, crafted to meet the most demanding industry standards. From stainless steel to high-performance nickel alloys, we offer a wide spectrum of materials for various industrial and environmental requirements.

Table of Contents

ToggleChoose your material to explore its advantages, applications, and available grades.

🧱 Stainless Steel

Grades: 304, 304L, 316, 316L, 310, 321, 347

Stainless steel is the backbone of our fastener range — corrosion-resistant, durable, and cost-effective. Ideal for marine, food processing, chemical, and architectural applications.

✅ Corrosion Resistance

✅ High Strength-to-Weight Ratio

✅ Non-reactive Surface for Sanitary Environments

🌊 SMO 254

SMO 254 is a super-austenitic stainless steel known for its exceptional resistance to pitting, crevice corrosion, and chloride stress. It outperforms standard austenitic grades in seawater and chemical environments.

Ideal For: Desalination plants, offshore platforms, heat exchangers.

✅ Superior Chloride Resistance

✅ High Molybdenum Content

✅ Weldability with High Strength

⚒️ Duplex Steel

Grades: UNS S31803, S32205

Duplex stainless steel combines the benefits of austenitic and ferritic steels — offering high strength and excellent resistance to corrosion and cracking.

Used In: Pulp and paper, chemical processing, pressure vessels.

✅ Twice the Strength of 304/316

✅ Good Fatigue Resistance

✅ Cost-Efficient for High-Strength Needs

🔩 Super Duplex Steel

Grades: UNS S32750, S32760

An enhanced version of duplex, Super Duplex is preferred for critical offshore and oil & gas structures due to its superior tensile strength and exceptional corrosion resistance.

✅ Extreme Mechanical Strength

✅ Excellent Resistance in Aggressive Chloride Environments

✅ Lower Maintenance Lifecycle

🔥 Inconel

Grades: Inconel 600, 625, 718

Inconel is a nickel-chromium-based alloy perfect for high-temperature and oxidation-prone applications.

Applications: Aerospace, nuclear reactors, marine exhausts.

✅ Oxidation & Heat Resistance

✅ High Performance in Extreme Environments

✅ Creep Resistance under Stress

⚗️ Monel

Grades: Monel 400, K500

Monel is a nickel-copper alloy known for its excellent resistance to seawater, steam, and acidic environments.

Common Uses: Shipbuilding, pump shafts, and chemical plants.

✅ High Resistance to Saltwater

✅ Maintains Toughness at Sub-Zero Temperatures

✅ Work-Hardenable

🧪 Hastelloy

Grades: Hastelloy C22, C276

Engineered for severe chemical environments, Hastelloy offers unmatched protection against strong oxidizers, reducing agents, and acids.

Best For: Chemical reactors, pickling equipment, pollution control systems.

✅ Universal Corrosion Resistance

✅ Non-Magnetic Alloy

✅ Superior Fabricability

🌐 Incoloy

Grades: Incoloy 800, 825

Incoloy alloys are known for their stability at high temperatures and resistance to carburization and oxidation.

Applications: Nuclear power, pressure vessels, heat exchangers.

✅ Strong in Sulfidizing and Oxidizing Environments

✅ High Strength at Elevated Temperatures

✅ Excellent Formability

🧲 Nickel Alloys

Nickel alloys provide a high level of corrosion resistance, especially in reducing conditions. They are ideal for electrical components and extreme chemical applications.

Used In: Aerospace, electronics, power generation.

✅ High Thermal & Electrical Conductivity

✅ Magnetic & Non-Magnetic Grades Available

✅ Stable at High Temperatures

💬 Need Help Choosing the Right Material?

Let our technical team guide you in selecting the ideal material based on your project’s operating environment and performance requirements.

📞 +91-8968469570 | ✉️ susheel@smfastners.com